To buy color coated aluminum sheet, you must choose painted aluminum sheet manufacturers with a good reputation. If you don’t know enough about the partner and choose a trading company, communication problems will occur, which will affect the quality of the project and the construction period. Aluminum painted sheet has become a ubiquitous application in the society, and the products qualitative problem is more obvious, and color coated aluminum sheet manufacturers are also emerging one after another. There are still many trading companies who use the information gap as an intermediary to earn the price difference. If you want to buy cost effective painted aluminum sheet products, you must choose an aluminium sheet manufacturer with a good reputation. So, how to choose a reliable manufacturer from the many so-called manufacturers?

What are the conditions that a qualified painted aluminum sheet manufacturer should have? As a qualified coated aluminum sheet manufacturer, there are three necessary conditions. A qualified painted aluminum sheet manufacturer should be a comprehensive enterprise integrating scientific research, design, production and installation. First of all, there must be an independent system that can independently complete product design and production, and requires certain scientific research capabilities to independently develop and improve products.

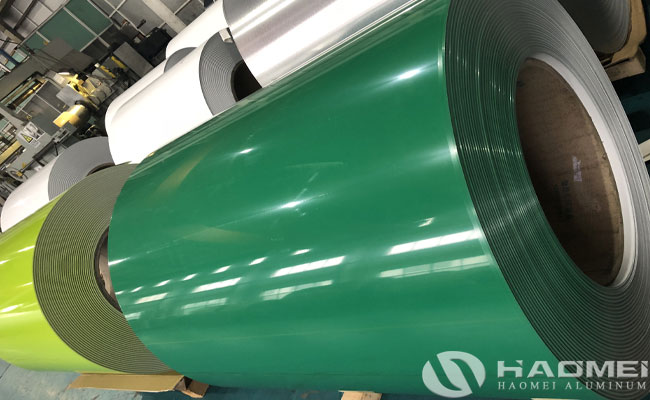

1, The quality assurance system requires quality inspection and packaging. High-precision special testing equipment is used to strictly inspect the product quality to ensure that the painted aluminium sheet size meets industry standards and the paint film quality meets relevant standards.

2, In terms of plate processing requirements, the painted aluminum sheet factory needs a complete set of cutting, stamping, bending and arc-shaped plates to ensure the processing of various complex and special-shaped plates with a basic size of 4 meters. There is a complete production process to ensure that the quality of the painted aluminum sheet meets the requirements.

3, The spraying process requires that in the pre-treatment process after spraying, the stains on the surface of the aluminum material should be cleaned with a chemical solution to remove the natural oxide layer of the plate. Then use chemical reagents to oxidize the wood, increase the adhesion of the wood, and ensure the quality of the paint in front. The painted aluminum sheet manufacturers must ensure that the coated aluminum sheet products are baked at the specified temperature and time.