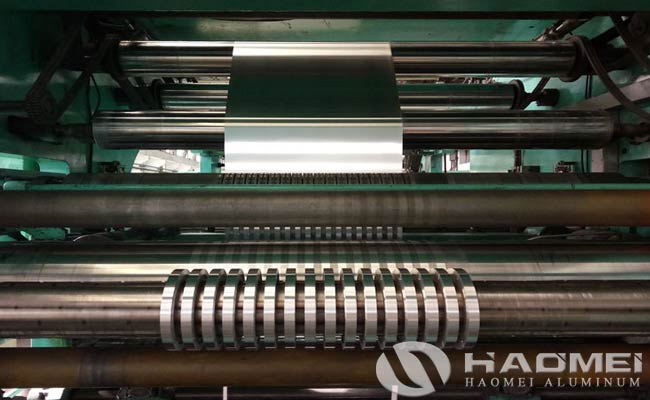

Slitted aluminum strip factories cut wide coils such as aluminum strips and copper strips into various width specifications. It is a processing technology for aluminum strip series products. The slitted aluminum strip has a small width error and its surface has no roller knife indentation, no rubber indentation, burr, etc., which meets the requirements of precision slitting. The aluminum strip slitting machine is a high-performance wide-width slitting equipment in aluminum strip factory. It absorbs the advantages of domestic and foreign models, has stable performance and convenient operation. It can slit pure aluminum tape or aluminum-plastic composite tape and hydrophilic aluminum foil. The machine is electrically clamped and automatically loaded, the finished product is rolled pneumatically, gas-liquid correction, materials are neatly cut, and the reel is tight. The performance of the machine is stable and the operation is convenient.

The slitted aluminum strip factories summarize main reason for the damage to the surface of the aluminum strip: there are a certain number of solid metal particles in the ingot,

① the surface of the ingot is attached to the surface of the ingot or the ingot is segregated. When there are many segregation floats on the surface of the ingot and the ingot has not been homogenized or the effect of homogenization is not good. When the metal flows through the working belt during the kneading process, these segregated floats or solid metal particles adhere to the surface of the working belt or cause damage to the working belt, and eventually scratch the surface of the aluminum strip;

②There are sundries on the working belt, The surface of the work belt is injured during kneading and scratches the aluminum strip; when it touches the aluminum strip, it scratches the surface of the aluminum strip;

③The discharge track or swing bed has exposed metal or graphite strips with hard inclusions Things. The aluminum strip was bruised because of the high speed.

Slitted aluminum strip factories also have Solution: Strengthen the control of the quality of the ingot; try to reduce the touch damage of the aluminum strip and auxiliary equipment. Use soft felt to block the aluminum strip from the auxiliary equipment. Try to avoid dragging or flipping the aluminum strip at will, and sort out foreign objects on the felt in time.