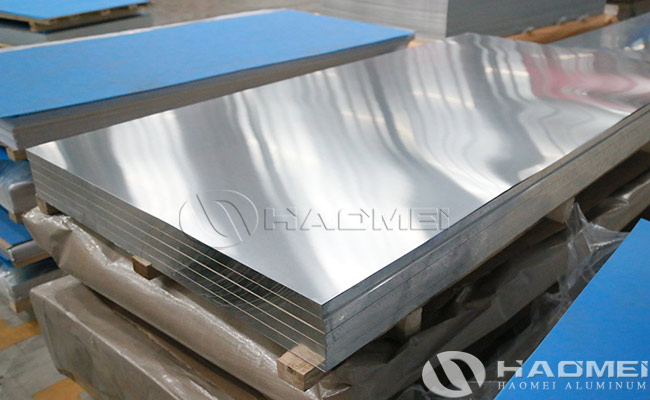

6061 aircraft aluminum alloy is a high-quality aluminum alloy product produced by heat treatment and pre-stretching process. Although its strength cannot be compared with 2000 series or 7000 series aircraft aluminum alloy, its magnesium and silicon alloys have many characteristics, such as excellent processing performance and excellent welding performance, And electroplating, good corrosion resistance, high toughness and no deformation after processing, dense material without defects. Aircraft aluminum sheet materials are several types of aluminum materials that are widely used in the aviation field. They have better mechanical and processing properties, and their mechanical and processing properties are much better than general aluminum materials. Common aircraft aluminum alloys are: 2024, 6061, 6063, 7075, etc. They have high strength, toughness, and various processing properties. For example, through hard oxidation, the hardness can reach above HRC55.

In order to explore the feasibility of 6061 aircraft aluminum sheet for aviation use, the mechanical properties, tensile fracture macromorphology, OM and SEM analysis of welded joints of 6061 aluminum alloy sheet in T42 state and T62 state were carried out by using mechanical and gold test methods. The test results show that the tensile strength of 6061 aluminum alloy is better, and the strength coefficients reach 95% and 91% respectively. The transverse tensile fracture modes of 6061 aircraft aluminum sheet alloy welded joints are all normal fractures perpendicular to the stress direction. All are heat-affected zones, and the fractures are all microscopic dimples.

Corrosion resistance, good strength, and weldability are the biggest advantages of 6061 aircraft aluminum alloy. At the same time, compared with steel, the weight of aluminum alloy is very light, based on these characteristics, 6061 aluminum alloy is often used as aviation fixtures, valve bodies, and parts.