Aluminium corrugated roofing sheets suppliers are able to produce a wide range of types of corrugated roofing sheets which are diverse in terms of alloy types and pattern designs. Below is a detailed summary of the alloy types and patterns that aluminum corrugated roofing sheets suppliers able to produce:

Corrugated aluminium roofing sheets are usually made from aluminum alloys, and common alloys include:

1. 3003 aluminum alloy: with good corrosion resistance and workability, it is commonly used in the manufacture of roofing sheets.

2. 3004 aluminum alloy: with high strength and corrosion resistance, it is suitable for roof panels that require higher strength.

3. 5052 aluminum alloy: with good corrosion resistance and strength, suitable for roof panels requiring higher performance.

4. 6061 Aluminum Alloy: Higher strength and hardness, suitable for roofing panels requiring higher strength and abrasion resistance.

Different alloy compositions will affect the performance and usage of aluminium corrugated roofing sheets. Customers can choose the appropriate alloy type according to their specific needs.

Corrugated aluminium roofing sheets can be classified into various types according to their uses, specifications and characteristics, including but not limited to:

Ordinary aluminum corrugated roofing sheet: used for general building roofs and walls, etc., with basic waterproof, anti-corrosion and weather-resistant properties.

Antique aluminum corrugated roofing sheets: Imitating the appearance and texture of traditional tiles, it is suitable for restoration of ancient buildings, antique buildings and other occasions.

Thermal insulation aluminum corrugated roofing sheets: Filled with thermal insulation materials inside the aluminum corrugated roofing sheet to improve the thermal insulation performance of the building.

Fireproof aluminum corrugated roofing sheet: Special techniques and materials are used to improve the fireproof performance of the aluminum corrugated roofing sheet, which is suitable for buildings with high fireproofing requirements.

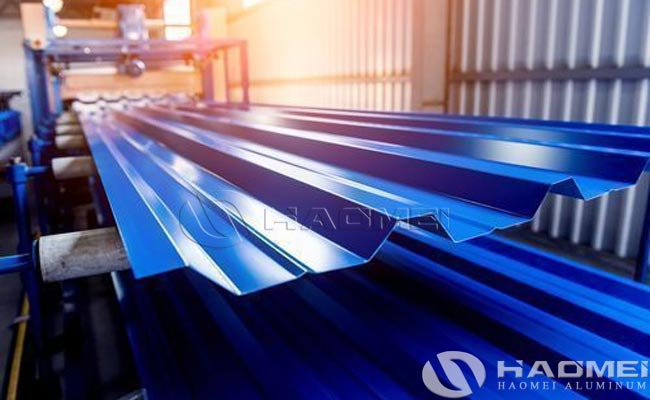

Color coated aluminum corrugated roofing sheet: The surface of the aluminum corrugated roofing sheet is color-coated to increase aesthetics and weather resistance, and is suitable for a variety of architectural decorations.

Corrugated aluminum roofing sheets are available in a wide variety of patterns to meet different architectural styles and decorative needs, and common patterns include:

Wave pattern: with an undulating wave shape to increase the beauty and three-dimensionality of the building.

Small wave pattern: suitable for occasions that require delicate texture, such as roofs and walls.

Antique tile pattern: imitating the texture of traditional tiles, suitable for antique buildings and ancient building restoration.

Flat plate type: with a flat surface, suitable for occasions requiring high flatness.

The product produced by different aluminium corrugated roofing sheets suppliers may differ in alloy type and pattern design, which should be selected according to the catalogs and samples provided by the manufacturers. When choosing aluminium corrugated roofing sheets, you need to consider the environment in which they will be used, load-bearing requirements, aesthetics and other factors to ensure that you choose the right product.