Rolling shutter doors and window blinds are mainly made of aluminum slits for roller shutter, which are durable and new, easy to clean, non-aging, non-fading, shading, heat insulation, ventilation, etc. Aluminum alloy roller shutter door is suitable for commercial facades, garages, shopping malls, hospitals, factories and mines. Enterprises and other public places or residential and other places.

Aluminum alloy rolling shutter door is a typical and common type of rolling shutter door. Its main characteristics are environmental protection, good anti-theft performance and easy cleaning, it is rich in color, and users can choose according to their personal preferences. The unique material and structural design of the rolling shutter made of the aluminum slit coil can effectively prevent strong light and ultraviolet radiation, completely solve the greenhouse effect caused by sunlight on the interior, and are suitable for various climate and weather changes. The environment has a long-term protective effect. Tests have shown that the shading rate of rolling shutter doors and windows to sunlight can reach 100%, and the shading rate to temperature can reach more than 95%.

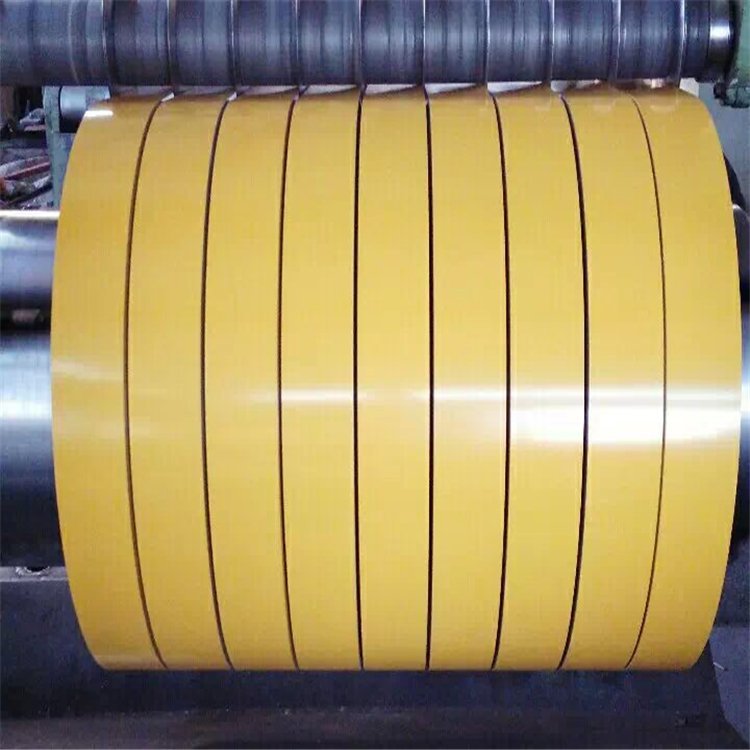

The aluminum alloy used for roller shutters are 3003 H24, preferably 3015/3105, H16 has better performance, mainly depends on whether the customer's equipment matches. The technical data of aluminum slits for roller shutter are:

Thickness: composite: foreign 0.17mm-0.25mm single piece without composite more than 0.3mm;

Paint: polyester paint on the front (usually scratch-resistant paint), epoxy back paint on the back (oil-based paint foams better than water-based paint);

Color: scratch-resistant white, beige, gray, black, brown, pearlescent metallic gray, pearlescent metallic brown, etc.

Color coated aluminum slits for roller shutter is similar to the aluminum alloy, but the thickness of the color aluminum is much thicker than the previous aluminum alloy, and it has been powder sprayed or electrophoresed. In the coloring treatment of the aluminum alloy surface, the aluminum alloy has very stable performance and is not easy to be corroded. Generally, the surface layer can be guaranteed not to fade for at least 30 years after special treatment.