The corrugated aluminum sheet is pressed by a press type device, and is usually named according to the corrugation height, the corrugation pitch, and the width after molding.

According to the thickness, the corrugated roofing aluminum sheet can be divided into various thicknesses such as 0.5, 0.6, 0.7, 0.8, 0.9, 1.0, 1.1, and 1.2, and can be divided into materials such as 1060, 3003, and 3004 according to the material.

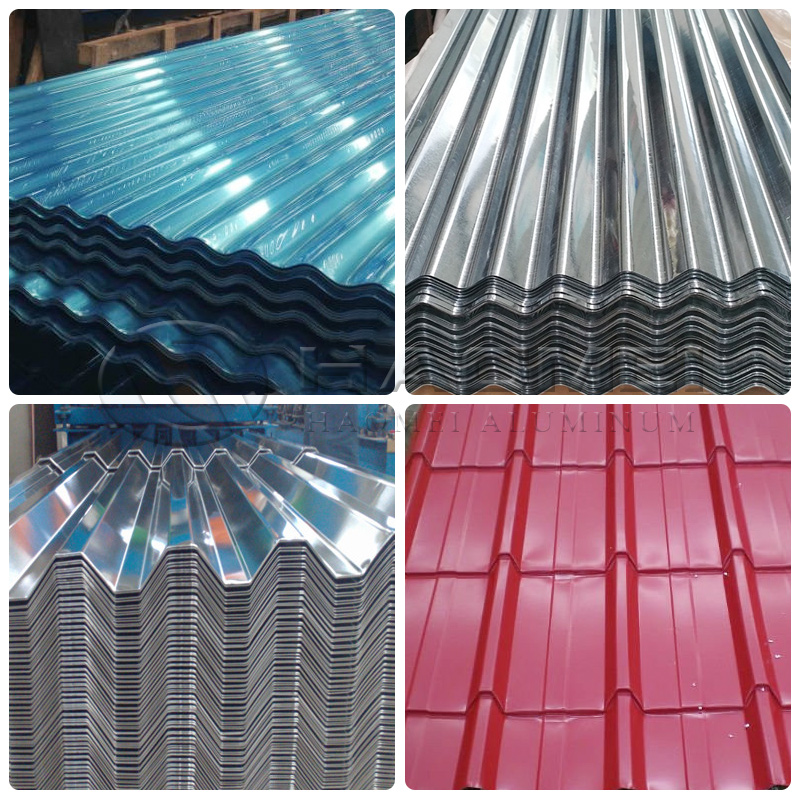

There are many types of corrugated aluminum sheets, including colored corrugated aluminum sheets, anticorrosive and corrugated aluminum sheet for decoration, colored aluminum corrugated aluminum sheets, fluorocarbon polyester corrugated aluminum sheets, aluminum watts of various colors, pressed aluminum sheets, and corrugated wavy aluminum sheets.

Corrugated board and corrugated aluminum sheet for building are suitable for industrial and civil buildings, warehouses, special buildings, roofs, walls and interior and exterior wall decoration of large-span steel structures. Corrugated aluminum sheet has the characteristics of light weight, high strength, rich color, convenient and quick construction, anti-seismic, fireproof, rainproof, long life and maintenance-free. It has been widely used. Many plastic extruded corrugated sheets, corrugated aluminum sheets, corrugated aluminum sheets have been produced, which are transparent, opaque and colored, and multi-layer composite hollow. Because of its good plasticity, it can better adapt to the requirements of various architectural styles, but it is superior to the color steel corrugated board with years of use, aesthetics and durability.