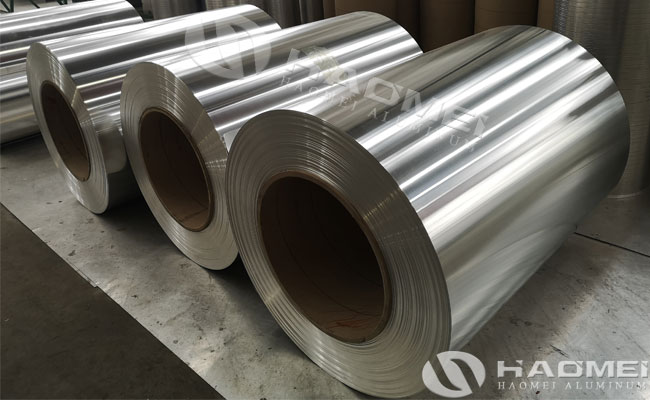

With its unique physical properties and wide range of applications, 1100 aluminum coil is an indispensable raw material for many industries in the metal processing and manufacturing industry. In this article, we'll take a closer look at the specifications, characteristics, and applications of 1100 aluminum coils in a variety of fields, revealing the unlimited possibilities of this material.

As a representative of industrial pure aluminum, 1100 aluminum coils are available in a variety of specifications to meet the needs of different industries. In terms of condition, 1100 aluminum coils are available in O state (annealed state), H14, H18, H22, H24, etc. to suit different processing and forming techniques. In terms of thickness, it ranges from 0.10mm to 4.5mm, while the width can be extended from 400mm to 2650mm or even wider, and the length can be customized according to customers' needs. This flexible and diverse specification design makes 1100 aluminum coil can be widely used in various scenarios.

The reason why 1100 aluminum coil is widely favored is due to its excellent physical and chemical properties. First, it has good ductility and formability, and is easy to process into various shapes and sizes. Second, 1100 aluminum coil has high corrosion resistance, electrical and thermal conductivity, and is able to maintain stable performance in a wide range of environments. In addition, its low density and light weight help reduce the overall weight and cost of products. Although the strength of 1100 aluminum coil is relatively low, this feature becomes an advantage in certain applications instead, such as those requiring good formability and corrosion resistance.

With its excellent performance, 1100 aluminum coil has been widely used in many industries.

- In the field of building decoration, it is often used to make curtain walls, aluminum composite panels and other decorative materials, which are not only beautiful and generous, but also corrosion-resistant and easy to maintain.

- In the electronic and electrical industry, 1100 aluminum coil has become an ideal material for PCB aluminum substrate and other electronic components due to its good conductivity and heat dissipation.

- In addition, in the chemical, food, pharmaceutical and other fields, 1100 aluminum coil is also widely used in the production of handling and storage equipment, sheet metal work products, etc., its high corrosion resistance and good formability for these industries to provide a reliable guarantee.

To sum up, 1100 aluminum coil occupies an important position in the metal processing and manufacturing industry with its flexible and diverse specifications, excellent performance and wide range of applications. Whether it is building decoration, electronic and electrical appliances or chemical and food industries, 1100 aluminum coil contributes to the development of each industry with its unique advantages. With the continuous progress of science and technology and the continuous expansion of the market, it is believed that the application prospect of 1100 aluminum coil will be even broader.